Steam Locomotive Injectors

How do you get water from a steam locomotive tender (which is at atmospheric pressure) into the boiler of a steam locomotive (which is at 175 to 300 psi)? A mechanical pump? Well, you could, but there is another way. You use the pressure of the boiler to push water back into it. Does this sound impossible? That is one of the reasons why an injector is such a marvelous device. An injector uses the venturi effect to inject water into the boiler using the boiler's own pressure. The Wikipedia page has a good description of this process.

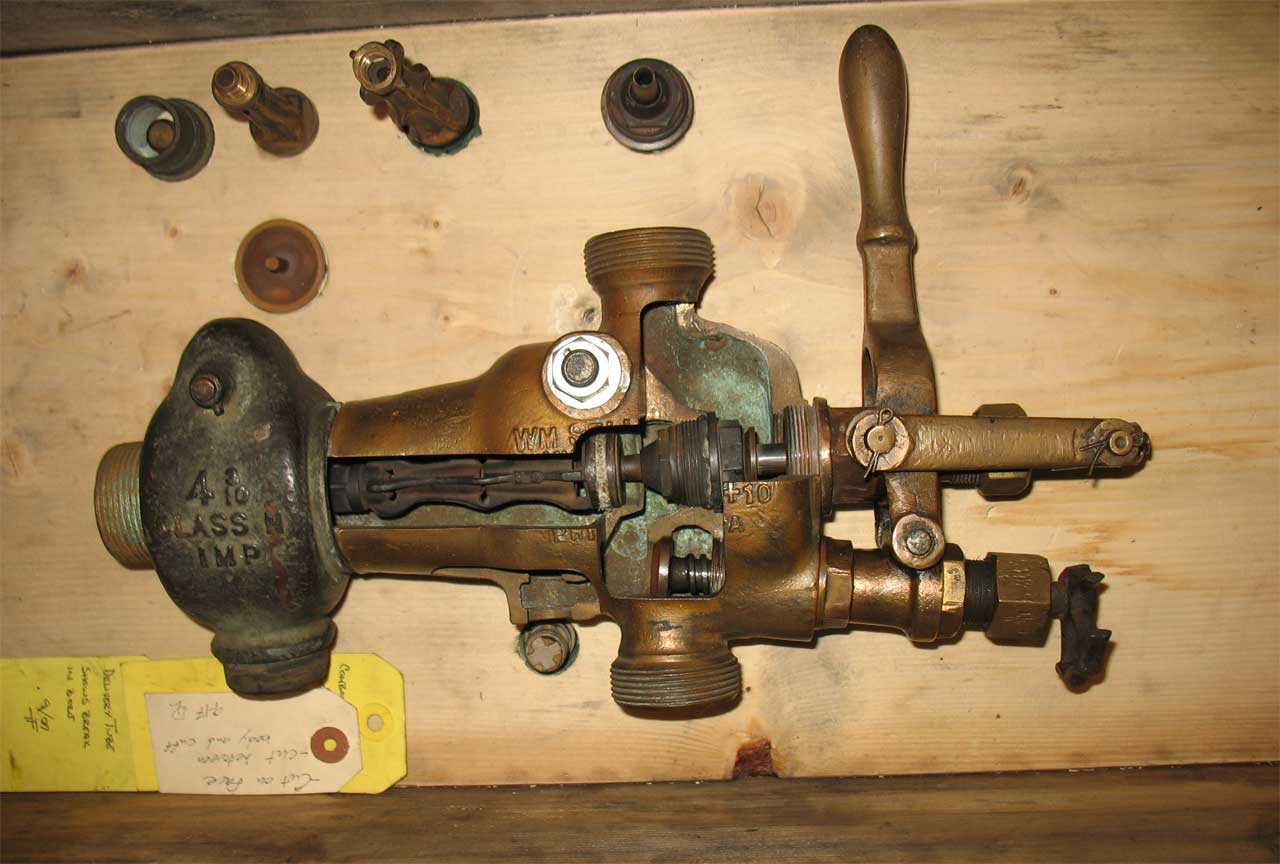

The injector of a steam locomotive could be a very temperamental device. Operating it was more complex than simply opening or closing a valve. The ones that I have operated were controlled by pulling a lever. The lever would be pulled partially in order to prime the injector and then pulled all the way to start injecting water. If the injector was not primed properly, it would not work. Getting an injector to "prime" was done by feeling and was more of an art than a skill.

Blowing off steam is a waste of fuel and water. Injectors were used to control much more than simply the level of water in the boiler. When a steam locomotive comes to rest (at a station) after having worked hard, there is a lot of thermal momentum. Firemen would often bring a locomotive into a station a little bit low on water so that the injectors could be used to add water. The added water is much colder than what is in the boiler. This was one way of controlling the boilder presser (and thermal momentum) to prevent the locomotive from blowing off (wasting) steam.